Four microns per ton

Early in my career I worked as both design consultant and owner's representative on a hydro-power project. That was 20 years ago. I was a 24-year old recent graduate with no experience in hydro-power whatsoever. I was employed at a big engineering consultancy. It was a time when there was so much demand for engineers that if you were willing to move to remote places (remote by Spanish standards, that is) you would get a lot of responsibility very fast.

The project manager on the owner's side was 4 or 5 years older than me, but he had no experience in hydro-power development either. He worked for a subsidiary of a big electricity firm. The firm had decided to centralize all renewable projects under the subsidiary, and that included small hydro-power as well.

The starting point for the project was the licensing documents. These were a set of plans that showed the proposed location and general shape of the hydro-power plant. The plans were not detailed enough to build from, and steel reinforcement was not part of the early stage design. Usually one would produce a detailed design before engaging a contractor, or enter into a design-build contract. But in this case, due to inexperience, the developer contracted simultaneously with the turbine manufacturer, which also supplied the alternator and auxiliary systems, for the detailed design and site supervision and with the civil works contractor.

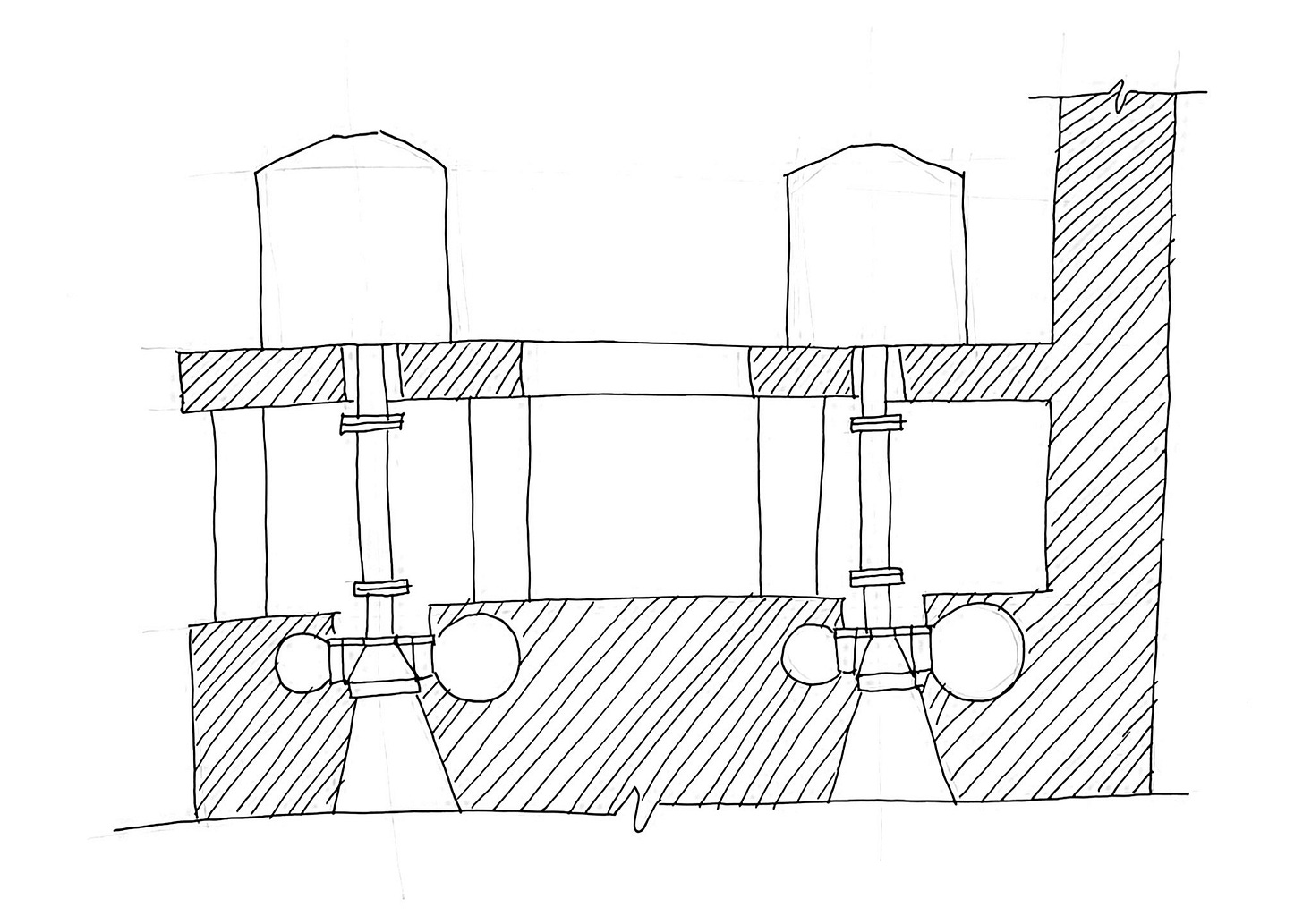

The start date was immediate and the contract required us to produce construction drawings 15 days in advance for when they would be required on site. That particular plant housed two vertical axis Francis turbines. To make maintenance easier and allow the turbine to be removed without having to dismount the alternator, the alternator was placed on an upper floor and was connected to the turbine with an extra-long shaft. This created an intermediate floor between the alternator and the turbine from which the turbine could be accessed.

Sketch of the plant.

During a design meeting, the structural engineer in charge of designing the floor and columns that would support the alternator, wanted to know what the allowable deformation was. A concrete floor experiences an instantaneous deformation when you put a load on it, but also a gradual deformation over time. This could affect the turbine clearance, so he asked the turbine manufacturer for the tolerances.

The manufacturer insisted that the tolerance was zero, and refused to give any other number. In the meeting there was also a senior engineer who had worked on the licensing documents, but he insisted that it was our job as consultants to know such things, and refused to give any number either. We sat there and the situation was becoming extremely uncomfortable, when a random manager from the electricity company entered the room. He had not been summoned to the meeting and he had nothing to do with the project. He just introduced himself and asked what we were working on. After a couple of minutes of small talk, the tolerances question came up. He informed us, without any hesitation, that four microns per ton of alternator weight would be fine. The conversation continued on other topics, and after a couple more minutes, he excused himself and went his way.

Given that the alternators weighed 80 tons, the four-microns rule implied an allowable deformation of 0.32mm. The structural engineer said it was fine; he could design the structure not to exceed it, and that was it. Twenty years later, I have not heard that there has been any problem with deformations at that plant.

To this day, I have so many questions. Why did that manager decide to attend a meeting he was not invited to? What kind of organization has managers attending random meetings to make small talk? I am thankful that the manager entered the room and settled our problem. But his answer still baffles me to this day. Turbine clearance is a hydraulic problem that should have nothing to do with alternator weight. Sources suggest that values between 0.5 and 1mm may be a good compromise between maintaining high turbine efficiency and allowing for inevitable deformations. The only justification that I can think of is that this is an empirical rule that reflects what is practically achievable, rather than what is theoretically required.